I put the drivers side in with no spring and shock and moved the suspension through its full range of motion and noticed a couple of things. Firstly, the top ball joint seems to reach the very very extremes of its range of motion just as the upper control arm hits the body. This is probably ok but I'd rather that it still had a few degrees of motion left. I'd like to know what happens on AUs at full bump, or on e-series with the AU conversion (BBQ Burner, you wanna do me a huge favour? PLEEEEZE???) because I don't think factory would be like this.

The shock (koni, hopefully it's the shortest - and consequently allows the most bump travel - that anyone will use) also bottoms out at exactly the same time, and at the same time as that the lower control arm *just* touches the chassis.

I think grinding 5mm of metal off the very lowest point of the chassis should be all that is needed to keep everything happy. When I went on a test drive it bottomed out hardish a few times (I had my ~50kg tool box in the RHS rear passenger seat as well, and the car is bloody low) and there is only a faint witness mark on the LCA even though I haven't yet "clearanced" the hole.

Bunged the brakes on, not happy with the brake lines. E-series is far too short, AU is acceptable for my test purposes but I would like to get a longer one that I can route behind the shock to ensure it can't rub or get caught. Not sure how I'm going to fix this without things becoming expensive (ie, custom rubber or aftermarket braided lines). I think racebrakes or that other mob just use a commodore braided line on their kits so I might find out what a set of those are worth.

NUT347 kindly lent me a couple of 17s to use as test rims, unfortunately the tyres are completely stuffed (not like I expected anything less

) so I used them at the start to check clearances at full bump travel and to see what the suspension does. It gets a lot of camber gain as the wheel moves upwards (which is good) but the toe changes noticeably, the further up the wheel goes the more toe in. I've not noticed anywhere near as much change on stock e-series before, and I've never looked at an AU, so I'm not sure if this is going to be a big issue.

) so I used them at the start to check clearances at full bump travel and to see what the suspension does. It gets a lot of camber gain as the wheel moves upwards (which is good) but the toe changes noticeably, the further up the wheel goes the more toe in. I've not noticed anywhere near as much change on stock e-series before, and I've never looked at an AU, so I'm not sure if this is going to be a big issue.

Dropped on the ground to have a look-see and roughly re-measure ride height and setback, at this stage it was within 2mm of what I got with the factory stuff in there, which I was quite chuffed with.

I fitted the other side and threw my 19s on (which are still for sale if anyone wants them!!) so I could check fitment and go for a test drive on tyres that didn't have canvas hanging out. I rechecked the ride height very roughly again and it seems it may have dropped about 10mm from stock, I'll have to recheck all this stuff properly on the wheel aligner at some stage. Might need to adjust the position of the hole for the shock bush to regain that ride height for 'production' versions, as the plan was to make these arms retain original ride height so people wouldn't have to get new springs or stuff about.

It's got some mega camber at the moment due to the right height, as you can see. The original suspension had a camber kit which we'd put about 6-8 thick shims in at each point to get the camber down to about 1 degree, when I put the AU stuff in I put 3 thick shims in each side just to see what would happen. I wanted to make these so that there was room for moar camber if people were going to attempt to stuff stupid rims under the front (I'm yet to try my 9.5" drifteks, but I definitely will asap

) so I'll probably end up putting a bunch more shims in when I put it on the aligner.

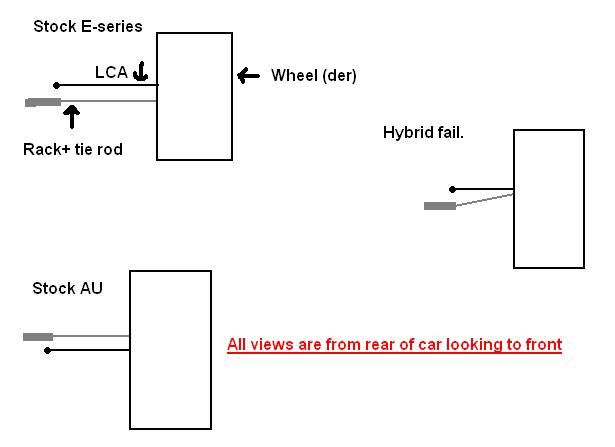

) so I'll probably end up putting a bunch more shims in when I put it on the aligner.The other thing that I suspected and has now become apparent is that EA-ED's will need EF-EL rack ends (I believe they're about 20mm longer) because the EA-ED ones are too short. I'm sure I grabbed some from the wreckers ages ago but couldn't for the life of me find them, so I had to seriously wind out the tie rods on the NC to get the toe anywhere close to straight, which is not cool. Will be getting some proper tie rods tomorrow hopefully.

Test drive went well, she just drove like a stocker

I've roughly calculated the area of the AU twin pistons compared to the e-series single, and it seems they have a slightly smaller total surface area. How this affects the bias in the real world is anybodies guess, as the larger surface area of the pads combined with the larger diameter rotor may compensate for the decreased piston surface area, or it may over or under compensate. I'd hazard a guess it will be fine though, and by the time you've fitted better pads and slotted rotors to anything it changes the bias anyway.

I've roughly calculated the area of the AU twin pistons compared to the e-series single, and it seems they have a slightly smaller total surface area. How this affects the bias in the real world is anybodies guess, as the larger surface area of the pads combined with the larger diameter rotor may compensate for the decreased piston surface area, or it may over or under compensate. I'd hazard a guess it will be fine though, and by the time you've fitted better pads and slotted rotors to anything it changes the bias anyway.