I had this issue on my NC which got progressively worse, so I decided to figure out what was causing it.

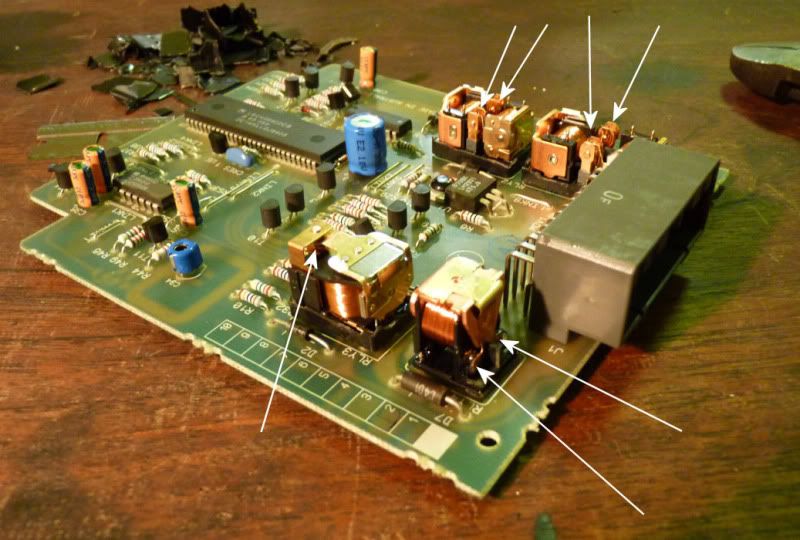

The first thing I did was pull the module out of the car (it's above the handbrake in boxcars, I'd assume in a similar place in bubblecars) and then pull the PCB out of the plastic case.

I suspected that the contacts in the relays had developed high resistance over the years so I thought I'd attempt to clean them.

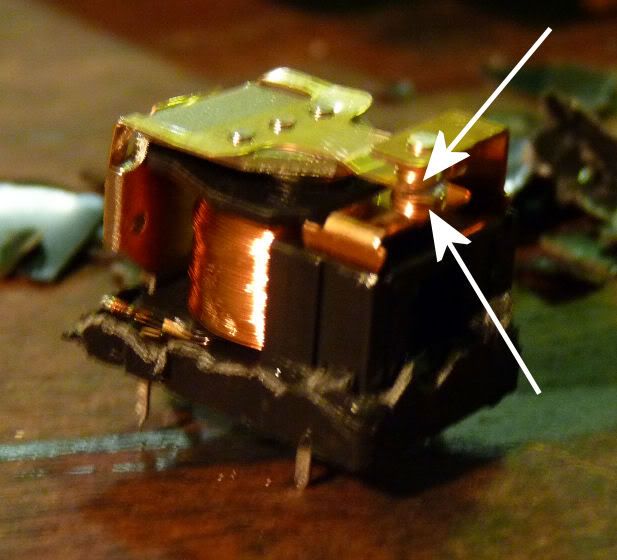

I de-soldered one of the relays and removed it from the board to see how/if it could be pulled apart. Unfortunately it doesn't seem possible to pull the covers off the relay without breaking the cover so I used a sharp razor blade and side cutters to break the cover off, exposing the relay.

Make sure when you do this that you are VERY CAREFUL as it would be quite easy to destroy the relay by cutting too deeply into the cover.

Once I'd investigated the first one I soldered it back on to the board and broke the covers carefully off the rest of the relays. It's not necessary to de-solder the relays to fix this issue, I just did it to see what I was working with initially.

Then I got a strip of 1200 grit sandpaper about 8mm wide and 50mm long and folded it in half lengthways, so it was now double sided and only 4mm wide.

With that piece of sandpaper I carefully poked it in between all the contacts of the relays and then gently sandpapered the contacts clean (arrows to show where I'm talking about).

The relays do have a lot more contacts than usual so make sure you do both sides when you are in there.

After cleaning the contacts I blew them out then put a little bit of Nyogel on them to try and stop/reduce the arcing across the contacts, put the PCB back in the box and back in the car. It's been 3 days now and it seems perfect, no more percussive maintenance needed.

. And car hasn't ever cranked over so easily before like it does now, was quite surprised at the difference it has made.

. And car hasn't ever cranked over so easily before like it does now, was quite surprised at the difference it has made.